Scratch Hardness Tester LINEARTESTER 249 Smart

Order number: 30800131-

Non-Binding Inquiry

With the button below you can add products to your product inquiry list if you want us to do a quote for this product.

Note this product

Scratch Hardness Testing

Scratch Hardness Tester LINEARTESTER 249 Smart

Scratch, rub, wipe - scratch hardness tests on sheet metal - Highly innovative. User-friendly. Precise.

The optimised ERICHSEN scratch hardness tester LINEARTESTER model 249 Smart.

- Table-top unit for determining the ability of a surface to resist damage by scratching

- Scribe/Scratch tests

- To and frocycle abrasion tests

- Crockmeter tests; MEK tests

- Tests determining the resistance against solvents in general or wipe test, respectively

- User-friendly operation via touch screen

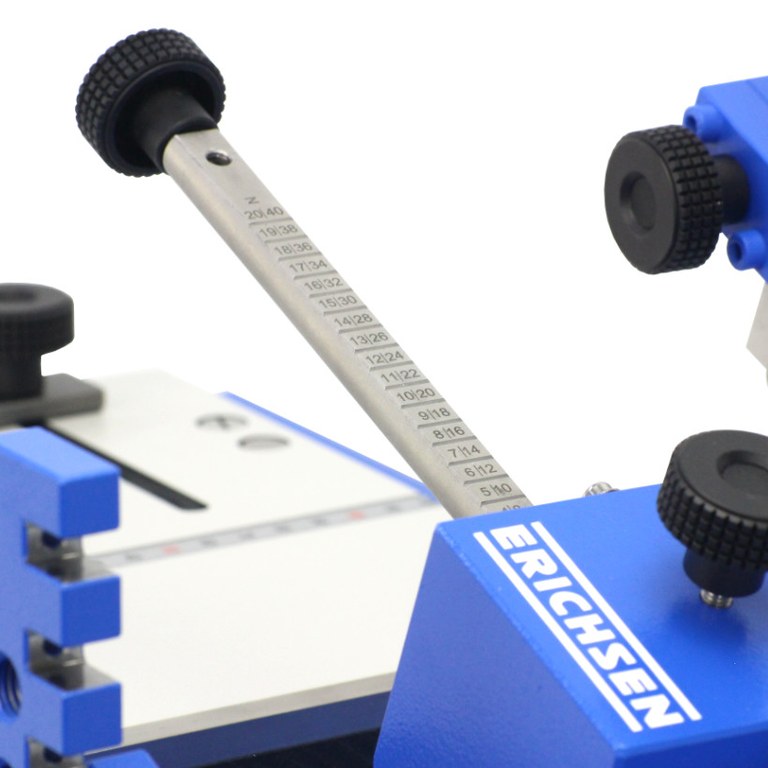

- Test force adjustable in the range 0.5 N - 20 N

- 4-way height-adjustable load arm with standard height approx. 10 mm (+20/+40/+60 mm)

- Set of sample clamps (order no. 21010332) required

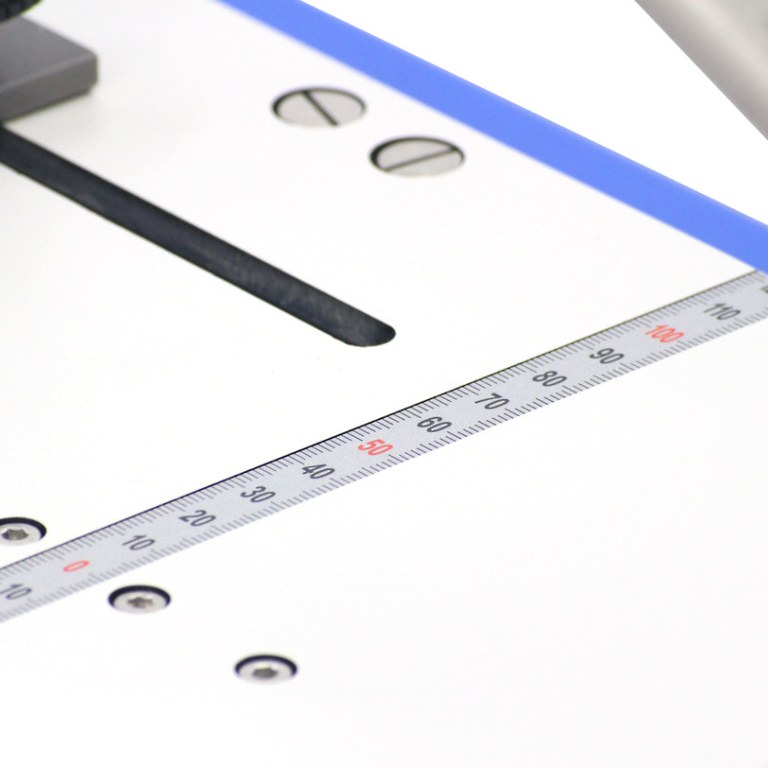

- A ruler embedded in the slide plate helps to maintain constant distances between scribing marks

- Electrical scribe detection for testing insulating coatings on conductive substrates

- Testing velocities are freely adjustable

- Variable stroke lengths

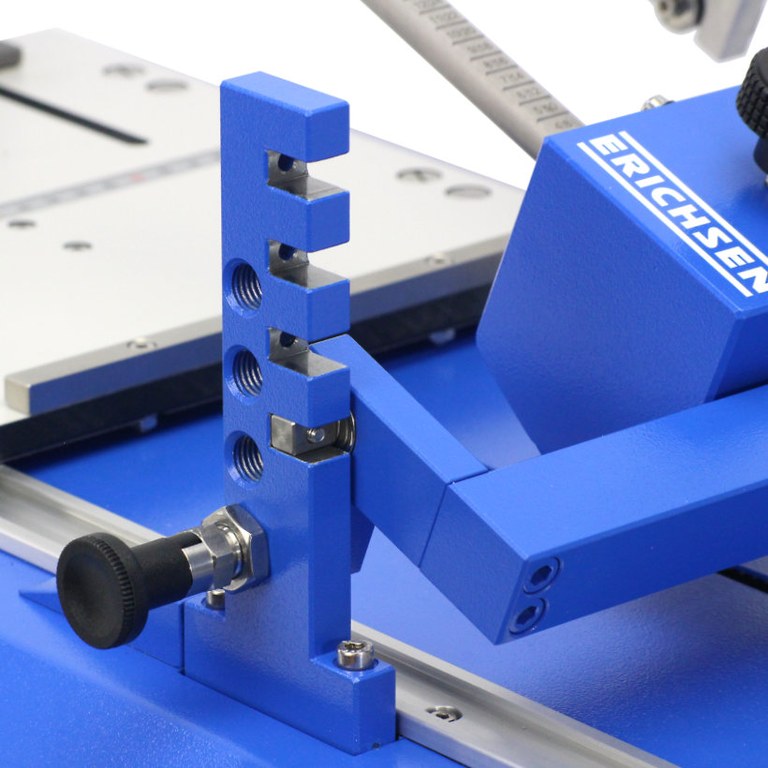

Design: The LINEARTESTER 249 Smart is a tabletop device that is operated via a capacitive LCD display. The electromotive drive ensures a uniform forward motion of the slide. The test tool is lowered and lifted automatically when scratch/scribe tests are carried out. A multitude of different test tools are available (see table in the technical description below). The tools marked with (*) are made of Tungsten Carbide Steel, additionally covered with an extremely hard layer. Due to this layer’s "golden" appearance, any worn parts are visually very easy recognizable because the Tungsten Carbide Material under the "golden" layer has a distincly different color. With the optional available universal adapter set (see last page of the technical description) even also several user-specifc tool inserts can be used.

Principle of the Test: The test panel is fixed onto a mobile slide by means of clamping rails. Above this slide and held on two metal pillars is a reciprocating beam bedded in a free-moving manner and carrying the adequate test tool as well as a weight. The required scratching force in the range of (0.5 to 20)N is set by moving the weight along the reciprocating beam, making use of a setting scale (an additional load weight of (1 to 40)N is optionally available). The testing machine is equipped with a 4-position height adjustable load arm device with standard height of about 10 mm (+20/+40/+60 mm). To use the vertical adjustment, a set of sample clamping pieces are also required (Order No. 21010332). Operation (settings) is via a capacitive LCD display.

To start a scratch/scribe test, the test tool is lowered onto the specimen when moving forward initiating the scratching process immediately. The test panel can be moved sideways so that a series of scratches can be carried out side by side with different force settings. Due to a ruler integrated in the slide plate, an uniform distance between the scratches can be achieved very easily.

When testing insulating coatings on conducting substrates, an electric recognition of the through-scratching offers an additional security for setting the scratching force.

For abrasion tests, crockmeter tests, MEK or wipe tests the test movement is carried out with the tool lowered onto the specimen, in preset cycles to and fro. For this, the guide plate has to be removed from the slide plate. The test speeds are freely adjustable. The LINEARTESTER Smart is equipped with variable stroke lengths.

Scope of delivery:

- Scratch hardness tester LINEARTESTER 249 Smart with electric motor drive; for scribe length single stroke 50 - 110 mm; double stroke 35 - 150 mm (without test tool)

- Load weight 20 N

- Operating instructions

Technical Descriptions

Norms

- ISO 1518

Technical specifications

Drive

Electric

Scratch profile

Van Laar, Bosch, ISO, Clemen, etc.

Testing Force

0.5 N - 20 N (for 1 N - 40 N accessory required)

Portable / Stationary

Stationary

Dimensions (L x W x H)

approx. 550 x 380 x 325 mm

Specimen dimensions

max. 210 x 210 mm

Test speed

Single stroke: (10 - 100)mm/s; double stroke: (10 - 400)mm/s infinitely adjustable

Test length

Single stroke: (50 - 110)mm

Stroke length

Double stroke: (35 - 150)mm variably adjustable

Equipment

Order number: 21010332

- 491.00 €

- Non-Binding Inquiry

Price excl. VAT. We sell to professional buyers

With the button below you can add products to your product inquiry list if you want us to do a quote for this product.

Note this product

Order number: 31390132

Mehr lesen...

- 716.00 €

- Non-Binding Inquiry

Price excl. VAT. We sell to professional buyers

With the button below you can add products to your product inquiry list if you want us to do a quote for this product.

Note this product

Order number: 32990232

Mehr lesen...

- 945.00 €

- Non-Binding Inquiry

Price excl. VAT. We sell to professional buyers

With the button below you can add products to your product inquiry list if you want us to do a quote for this product.

Note this product

Order number: 04330132

- 268.00 €

- Non-Binding Inquiry

Price excl. VAT. We sell to professional buyers

With the button below you can add products to your product inquiry list if you want us to do a quote for this product.

Note this product

Order number: 04330232

- 268.00 €

- Non-Binding Inquiry

Price excl. VAT. We sell to professional buyers

With the button below you can add products to your product inquiry list if you want us to do a quote for this product.

Note this product

Order number: 04330732

- 368.00 €

- Non-Binding Inquiry

Price excl. VAT. We sell to professional buyers

With the button below you can add products to your product inquiry list if you want us to do a quote for this product.

Note this product

Order number: 19610232

- 345.00 €

- Non-Binding Inquiry

Price excl. VAT. We sell to professional buyers

With the button below you can add products to your product inquiry list if you want us to do a quote for this product.

Note this product

Order number: 915030241

- 247.00 €

- Non-Binding Inquiry

Price excl. VAT. We sell to professional buyers

With the button below you can add products to your product inquiry list if you want us to do a quote for this product.

Note this product

Order number: 06930132

- 247.00 €

- Non-Binding Inquiry

Price excl. VAT. We sell to professional buyers

With the button below you can add products to your product inquiry list if you want us to do a quote for this product.

Note this product

Order number: 08420132

- 354.00 €

- Non-Binding Inquiry

Price excl. VAT. We sell to professional buyers

With the button below you can add products to your product inquiry list if you want us to do a quote for this product.

Note this product

Order number: 02080232

- 269.00 €

- Non-Binding Inquiry

Price excl. VAT. We sell to professional buyers

With the button below you can add products to your product inquiry list if you want us to do a quote for this product.

Note this product

Order number: 915030441

- 785.00 €

- Non-Binding Inquiry

Price excl. VAT. We sell to professional buyers

With the button below you can add products to your product inquiry list if you want us to do a quote for this product.

Note this product

Order number: 07410132

- 386.00 €

- Non-Binding Inquiry

Price excl. VAT. We sell to professional buyers

With the button below you can add products to your product inquiry list if you want us to do a quote for this product.

Note this product

Order number: 07400132

- 192.00 €

- Non-Binding Inquiry

Price excl. VAT. We sell to professional buyers

With the button below you can add products to your product inquiry list if you want us to do a quote for this product.

Note this product

Order number: 08400132

Mehr lesen...

- 221.00 €

- Non-Binding Inquiry

Price excl. VAT. We sell to professional buyers

With the button below you can add products to your product inquiry list if you want us to do a quote for this product.

Note this product

Order number: 08410132

- 89.00 €

- Non-Binding Inquiry

Price excl. VAT. We sell to professional buyers

With the button below you can add products to your product inquiry list if you want us to do a quote for this product.

Note this product

Order number: 08490132

Mehr lesen...

- 101.00 €

- Non-Binding Inquiry

Price excl. VAT. We sell to professional buyers

With the button below you can add products to your product inquiry list if you want us to do a quote for this product.

Note this product

Order number: 19100132

- 474.00 €

- Non-Binding Inquiry

Price excl. VAT. We sell to professional buyers

With the button below you can add products to your product inquiry list if you want us to do a quote for this product.

Note this product

Order number: 03640853

- 77.00 €

- Non-Binding Inquiry

Price excl. VAT. We sell to professional buyers

With the button below you can add products to your product inquiry list if you want us to do a quote for this product.

Note this product

Order number: 03644752

- 37.00 €

- Non-Binding Inquiry

Price excl. VAT. We sell to professional buyers

With the button below you can add products to your product inquiry list if you want us to do a quote for this product.

Note this product

Order number: 06900132

- 402.00 €

- Non-Binding Inquiry

Price excl. VAT. We sell to professional buyers

With the button below you can add products to your product inquiry list if you want us to do a quote for this product.

Note this product

Order number: 05390132

- 247.00 €

- Non-Binding Inquiry

Price excl. VAT. We sell to professional buyers

With the button below you can add products to your product inquiry list if you want us to do a quote for this product.

Note this product

Order number: 05390232

- 221.00 €

- Non-Binding Inquiry

Price excl. VAT. We sell to professional buyers

With the button below you can add products to your product inquiry list if you want us to do a quote for this product.

Note this product

Order number: 05390332

Mehr lesen...

- 242.00 €

- Non-Binding Inquiry

Price excl. VAT. We sell to professional buyers

With the button below you can add products to your product inquiry list if you want us to do a quote for this product.

Note this product

Order number: 05390732

Mehr lesen...

- 509.00 €

- Non-Binding Inquiry

Price excl. VAT. We sell to professional buyers

With the button below you can add products to your product inquiry list if you want us to do a quote for this product.

Note this product

Order number: 05390432

- 234.00 €

- Non-Binding Inquiry

Price excl. VAT. We sell to professional buyers

With the button below you can add products to your product inquiry list if you want us to do a quote for this product.

Note this product

Order number: 02180232

- 286.00 €

- Non-Binding Inquiry

Price excl. VAT. We sell to professional buyers

With the button below you can add products to your product inquiry list if you want us to do a quote for this product.

Note this product

Order number: 05640132

- 497.00 €

- Non-Binding Inquiry

Price excl. VAT. We sell to professional buyers

With the button below you can add products to your product inquiry list if you want us to do a quote for this product.

Note this product

Order number: 05391332

- 778.00 €

- Non-Binding Inquiry

Price excl. VAT. We sell to professional buyers

With the button below you can add products to your product inquiry list if you want us to do a quote for this product.

Note this product

Order number: 04300132

- 57.00 €

- Non-Binding Inquiry

Price excl. VAT. We sell to professional buyers

With the button below you can add products to your product inquiry list if you want us to do a quote for this product.

Note this product

Order number: 04300232

- 57.00 €

- Non-Binding Inquiry

Price excl. VAT. We sell to professional buyers

With the button below you can add products to your product inquiry list if you want us to do a quote for this product.

Note this product

Order number: 04300332

- 57.00 €

- Non-Binding Inquiry

Price excl. VAT. We sell to professional buyers

With the button below you can add products to your product inquiry list if you want us to do a quote for this product.

Note this product

Order number: 04300432

- 85.00 €

- Non-Binding Inquiry

Price excl. VAT. We sell to professional buyers

With the button below you can add products to your product inquiry list if you want us to do a quote for this product.

Note this product

Order number: 08440132

- 108.00 €

- Non-Binding Inquiry

Price excl. VAT. We sell to professional buyers

With the button below you can add products to your product inquiry list if you want us to do a quote for this product.

Note this product

Order number: 08450132

- 108.00 €

- Non-Binding Inquiry

Price excl. VAT. We sell to professional buyers

With the button below you can add products to your product inquiry list if you want us to do a quote for this product.

Note this product